Polyacrylic acid

| |||||||||||||||||||||||||||||||||||||||||||||||||

Read other articles:

Successors to General Electric's 600-series mainframes Honeywell 6000 SeriesManufacturerHoneywell Inc.Release date1970; 54 years ago (1970)Operating systemGCOS, Multics, CP-6PredecessorGE-600 series The Honeywell 6000 series computers were rebadged versions of General Electric's 600-series mainframes manufactured by Honeywell International, Inc. from 1970 to 1989. Honeywell acquired the line when it purchased GE's computer division in 1970 and continued to develop them under...

Guatemalan football club This article is about the Guatemalan football club. For the Canadian soccer club, see Aurora FC (Canada). Football clubAuroraFull nameAurora Fútbol ClubNickname(s)Los Militares (The Military)Founded1945; 78 years agoGroundEstadio Cementos ProgresoCapacity14,022ChairmanArmy of GuatemalaManagerGabriel CastilloLeaguePrimera DivisiónApertura 2023Group B 5th (Quarterfinals) Home colours Away colours Aurora Fútbol Club is a Guatemalan professional football club. They are...

Stasiun Cibatu C29 Tampak depan Stasiun Cibatu tahun 2019LokasiCibatu, Cibatu, Garut, Jawa Barat 44185IndonesiaKoordinat7°6′0.414″S 107°58′46.081″E / 7.10011500°S 107.97946694°E / -7.10011500; 107.97946694Koordinat: 7°6′0.414″S 107°58′46.081″E / 7.10011500°S 107.97946694°E / -7.10011500; 107.97946694Ketinggian+612 mOperator Kereta Api IndonesiaDaerah Operasi II Bandung KAI Commuter Letak km 213+631 lintas Bogor–Bandung�...

Sean Kelly Personal informationFull name Sean KellyDate of birth (1993-11-01) 1 November 1993 (age 30)Place of birth Glasgow, ScotlandHeight 1.88 m (6 ft 2 in)Position(s) DefenderTeam informationCurrent team LivingstonNumber 24Senior career*Years Team Apps (Gls)2012–2016 St Mirren 90 (6)2012 → East Stirlingshire (loan) 10 (0)2016–2017 AFC Wimbledon 26 (2)2017–2020 Ross County 51 (1)2020–2021 Falkirk 14 (0)2021– Livingston 61 (5)International career‡2014 Scot...

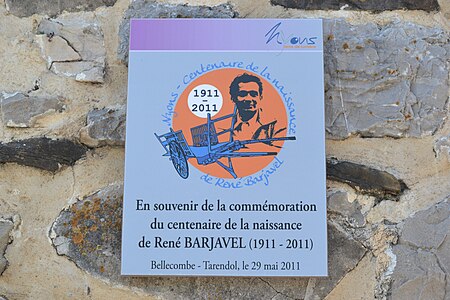

Pour les articles homonymes, voir Barjavel. René BarjavelRené Barjavel en 1949. Photo d'identité (Sacem).BiographieNaissance 24 janvier 1911Nyons (Drôme, France)Décès 24 novembre 1985 (à 74 ans)14e arrondissement de Paris (France)Sépulture Bellecombe-TarendolNom de naissance René Henri Gustave BarjavelNationalité françaiseActivité Romancier, nouvelliste, essayiste, chroniqueur, journaliste, scénariste, dialoguistePériode d'activité 1942-1985Autres informationsConflit Seco...

Hermann Obrecht Anggota Dewan Federal SwissMasa jabatan4 April 1935 – 31 Juli 1940 PendahuluEdmund SchulthessPenggantiWalther Stampfli Informasi pribadiLahir(1874-11-27)27 November 1874Meninggal8 September 1953(1953-09-08) (umur 78)KebangsaanSwissSunting kotak info • L • B Hermann Obrecht (26 Maret 1882 - 21 Agustus 1940) adalah politikus Swiss dan Anggota Dewan Federal Swiss (1935-1940). Ia terpilih di Dewan Federal Swiss pada 4 April 1935 hingga meletakkan jaba...

Dalam nama Tionghoa ini, nama keluarganya adalah Zeng. Zeng GuangZeng GuangNama asal曾光Lahir22 Mei 1946 (umur 77)Beijing, TiongkokKarier ilmiahBidangEpidemiologiInstitusiPusat Pengendalian dan Pencegahan Penyakit Tiongkok Zeng Guang (Hanzi: 曾光; Pinyin: Zēng Guāng; lahir 22 Mei 1946) adalah seorang epidemiologis Tiongkok yang menjadi kepala ilmuwan dan petinggi doktoral di Pusat Pengendalian dan Pencegahan Penyakit Tiongkok.[1] Ia adalah anggota Panel Pakar T...

2017 musical about the K-pop industry KPOPPlaybill for the Broadway productionMusicHelen Park Max VernonLyricsHelen Park Max VernonBookJason KimBasisK-popPremiereSeptember 5, 2017 (2017-09-05): Ars Nova, Midtown Manhattan, New York CityProductions2017 Off-Broadway2022 BroadwayAwardsLucille Lortel Award for Outstanding Musical KPOP is a Broadway musical with a book by Jason Kim and music and lyrics by Helen Park and Max Vernon. The musical originally premiered Off-Broadway at Ar...

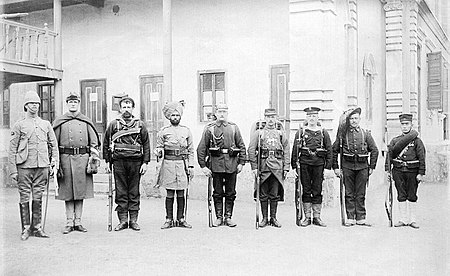

Expedition to China This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed.Find sources: China Relief Expedition – news · newspapers · books · scholar · JSTOR (June 2011) (Learn how and when to remove this message) China Relief ExpeditionComponents 9th Infantry Regiment 14th Infantry Regiment 6th Cavalry Regiment Light Battery F...

Questa voce o sezione sull'argomento cattolicesimo non cita le fonti necessarie o quelle presenti sono insufficienti. Puoi migliorare questa voce aggiungendo citazioni da fonti attendibili secondo le linee guida sull'uso delle fonti. Segui i suggerimenti del progetto di riferimento. Sala stampa della Santa Sede È lo speciale ufficio dipendente dalla Prima Sezione della Segreteria di Stato che pubblica e divulga le comunicazioni ufficiali riguardanti sia gli atti del Sommo Pontefice sia...

Indonesian Movie Awards ke-7Tanggal27 Mei 2013TempatStudio 8 RCTI, JakartaPembawa acara Choky Sitohang Tamara Geraldine Ivan Gunawan Donita PenyelenggaraRCTISorotanFilm Terbaik: Pilihan pemirsaHabibie & AinunAktor TerbaikLukman Sardi(Rectoverso)Aktris TerbaikImelda Therinne(Belenggu)Penghargaan seumur hidupAminah CendrakasihLiputan televisiSaluranRCTI ← 2012 Indonesian Movie Awards 2014 → Indonesian Movie Awards 2013 adalah penghargaan film Indonesian Movie Awards ya...

هذه المقالة عن المجموعة العرقية الأتراك وليس عن من يحملون جنسية الجمهورية التركية أتراكTürkler (بالتركية) التعداد الكليالتعداد 70~83 مليون نسمةمناطق الوجود المميزةالبلد القائمة ... تركياألمانياسورياالعراقبلغارياالولايات المتحدةفرنساالمملكة المتحدةهولنداالنمساأسترالي�...

Успенский собор Кирилло-Белозерского монастыря Кири́лловское викариа́тство — викариатство Новгородской епархии Русской Православной Церкви. Кирилловское викариатство Новгородской епархии было учреждено 21 ноября 1892 года, взамен упразднённой, а позже восстановлен...

Airport in Chobham, SurreyFairoaks AirportFairoaks Control Tower in 2006IATA: noneICAO: EGTFSummaryAirport typePrivate-owned, Public-useOwnerAlbemarle Fairoaks Airport Ltd. and Airport Development PartnersOperatorFairoaks Operations Ltd.ServesWokingLocationChobham, SurreyElevation AMSL80 ft / 24 mCoordinates51°20′53″N 000°33′31″W / 51.34806°N 0.55861°W / 51.34806; -0.55861MapEGTFLocation in SurreyRunways Direction Length Surface m ft 06/24 8...

Category 5 Atlantic hurricane in 2005 This article is about the Atlantic hurricane in 2005. For other storms of the same name, see List of storms named Rita. Hurricane Rita Rita near peak intensity on September 21Meteorological historyFormedSeptember 18, 2005DissipatedSeptember 26, 2005Category 5 major hurricane1-minute sustained (SSHWS/NWS)Highest winds180 mph (285 km/h)Lowest pressure895 mbar (hPa); 26.43 inHgOverall effectsFatalities120Damage$18.5 billio...

Institutional corruption in the country Political corruption Forms and concepts Bribery Cronyism Economics of corruption Electoral fraud Elite capture Influence peddling Kleptocracy Mafia state Nepotism Pyrrhic defeat theory Slush fund Simony State capture State-corporate crime Throffer Anti-corruption International Anti-Corruption Court Group of States Against Corruption International Anti-Corruption Academy International Anti-Corruption Day United Nations Convention against Corruption Corru...

German politician Christian HaaseHaase in 2020Member of the BundestagIncumbentAssumed office 2013 Personal detailsBorn (1966-05-06) 6 May 1966 (age 58)Höxter, West Germany(now Germany)Political partyCDU Christian Haase (born 6 May 1966) is a German politician of the Christian Democratic Union (CDU) who has been serving as a member of the Bundestag from the state of North Rhine-Westphalia since 2013.[1] Political career Haase became a member of the Bundestag in the 2013 Germ...

For Tielen in Germany, see Tielen, Germany. This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed.Find sources: Tielen – news · newspapers · books · scholar · JSTOR (May 2022) (Learn how and when to remove this message) Village in Flemish RegionTielenVillageView on the village centreTielenLocation in BelgiumCoordinates: 51°14�...

Pour les articles homonymes, voir Van Beneden. Édouard Van Beneden Édouard Van Beneden Données clés Naissance 5 mars 1846Louvain (Belgique) Décès 28 avril 1910Liège (Belgique) Nationalité Belgique Données clés Domaines zoologiste, embryologiste Institutions Université de Liège Renommé pour Découverte de la méiose Distinctions Prix quinquennal des Sciences en 1871, 1887 et 1891 modifier Édouard Joseph Louis Marie Van Beneden, né à Louvain le 5 mars 1846 et mort à Liège le ...

Mudasarlova ParkLocationChinna Gadhili Visakhapatnam, Andhra Pradesh, IndiaArea20 acres (8.1 ha)Created1902 (1902)Operated byVMRDA Mudasarlova Park is an urban park in the Indian city of Visakhapatnam. It is spread over 20 acres (8.1 ha) of land. it was constructed in 1902 and is one of the oldest parks in this Coastal Andhra. The water reservoir in the park supplies drinking water to the city.[1] It was named one of the best picnic spots for local citizens.[c...