Manufacturing in New Zealand

|

Read other articles:

Anugerah Musik Indonesia 1998Tanggal21 Oktober 1998LokasiTeater Taman Ismail Marzuki, Jakarta PusatNegaraIndonesiaIkhtisarPenghargaan terbanyakChrisye (4)Pencipta Lagu Terbaik-TerbaikKala Cinta Menggoda – Guruh SoekarnoputraAlbum Terbaik-TerbaikKala Cinta Menggoda – ChrisyePendatang Baru Terbaik-TerbaikReza ArtameviaSitus webami-awards.comSiaran televisi/radioSaluranIndosiarWaktu tayang180 menitProduserYayasan Anugerah Musik Indonesia← 1997 Anugerah Musik Indonesia1999 → Anuge...

Cao Kun 6th Presiden Republik TiongkokMasa jabatan10 Oktober 1923 – 2 November 1924Perdana MenteriGao LingweiSun BaoqiKu Wei-chün PendahuluGao Lingwei (Pejabat)PenggantiHuang Fu (Pejabat) Informasi pribadiLahir(1862-12-12)12 Desember 1862Tianjin, Kekaisaran TiongkokMeninggal15 Mei 1938(1938-05-15) (umur 75)Tianjin, Republik TiongkokPartai politikKelompok ZhiliKarier militerPihak Dinasti Qing Republik Tiongkok Kekaisaran TiongkokKelompok ZhiliPangkatJenderalPertempuran/pe...

This article is about the common name for many species of fish. For the genus, see Tilapia (genus).Common name for many species of fish Nile tilapia, Oreochromis niloticusGlobal harvest of tilapia in million tonnes as reported by the FAO, 1950–2009[1] Tilapia (/tɪˈlɑːpiə/ tih-LAH-pee-ə) is the common name for nearly a hundred species of cichlid fish from the coelotilapine, coptodonine, heterotilapine, oreochromine, pelmatolapiine, and tilapiine tribes (formerly all were Tilapi...

العلاقات الجيبوتية المنغولية جيبوتي منغوليا جيبوتي منغوليا تعديل مصدري - تعديل العلاقات الجيبوتية المنغولية هي العلاقات الثنائية التي تجمع بين جيبوتي ومنغوليا.[1][2][3][4][5] مقارنة بين البلدين هذه مقارنة عامة ومرجعية للدولتين: وجه المقا...

American politician The ReverendJamila WoodsWoods in 2023Member of the Maryland House of Delegatesfrom the 26th districtIncumbentAssumed office January 11, 2023Serving with Veronica L. Turner and Kris ValderramaPreceded byJay Walker Personal detailsBorn (1963-07-09) July 9, 1963 (age 60)Camden, New Jersey, U.S.Political partyDemocraticChildren2EducationHoward University (BA, MDiv)University of Maryland, Baltimore (MS)OccupationPastorWebsiteCampaign website Jamila ...

Caballeros de la Orden del Santo Sepulcro en la actualidad, con su hábito blanco y la cruz característica. Cruz de la Orden del Temple (templarios). Moneda de la Orden de San Juan de Jerusalén (antes del Hospital -hospitalarios- y luego de Malta), con la cruz que la identifica. Cruces de las órdenes militares españolas (desde arriba): Santiago, Alcántara, Calatrava y Montesa). Francisco Farnesio, duque de Parma, en hábito de caballero de San Jorge (Sagrada Orden Militar Constantiniana)...

ASEAN University GamesAbbreviationAUGFirst event1981 Chiang Mai, ThailandOccur every2 yearsLast event2022 Ubon Ratchathani, ThailandNext event2024 Surabaya and Malang, Indonesia ASEAN University Sports Council (AUSC)Formation1980TypeSports federationHeadquartersKuala Lumpur, MalaysiaMembership 11 countriesOfficial language EnglishWebsiteausc.my ASEAN University Games (AUG) is a biennial sports event that involves athletes from the universities of the ASEAN member countries. It is regulated b...

For the competition in Cornwall, see World Pasty Championships. International Pasty FestivalFestival Internacional del PasteStatusactiveGenreFood festivalDate(s)October, 3 daysFrequencyAnnuallyLocation(s)Real del Monte, HidalgoCoordinates20°08′18″N 98°40′23″W / 20.138216°N 98.673163°W / 20.138216; -98.673163CountryMexicoInaugurated2009 The International Pasty Festival (Spanish: Festival Internacional del Paste) is an annual festival celebrating the pasty th...

Men's golf competition between the United States and Europe in September and October 2023 44th Ryder Cup MatchesDates29 September – 1 October 2023VenueMarco Simone Golf and Country ClubLocationGuidonia Montecelio, Metropolitan City of Rome Capital, ItalyCaptainsLuke Donald[a] (Europe)Zach Johnson (USA) 161⁄2 111⁄2 Europe wins the Ryder CupLocation mapMarco Simone G&CCLocation in ItalyShow map of ItalyMarco Simone G&CCLocation in LazioShow map of LazioMarco Simone...

Artikel ini perlu dikembangkan agar dapat memenuhi kriteria sebagai entri Wikipedia.Bantulah untuk mengembangkan artikel ini. Jika tidak dikembangkan, artikel ini akan dihapus. Artikel ini membutuhkan rujukan tambahan agar kualitasnya dapat dipastikan. Mohon bantu kami mengembangkan artikel ini dengan cara menambahkan rujukan ke sumber tepercaya. Pernyataan tak bersumber bisa saja dipertentangkan dan dihapus.Cari sumber: Marah Halim Harahap – berita · surat kabar �...

Traditional British pudding Eve's puddingA home-made Eve's puddingTypePuddingPlace of originUnited KingdomMain ingredientsVictoria sponge cake, apples Media: Eve's pudding Eve's pudding, also known as Mother Eve's pudding, is a type of traditional British pudding made from apples baked under a Victoria sponge cake mixture.[1] The name is a reference to the apple variety traditionally used (an eating apple) called Eve.[2] The pudding can be served with custard, cream,...

Football stadium, home of Liverpool F.C. This article is about the football stadium. For the area of Liverpool in which the stadium is located, see Anfield (suburb). For other uses, see Anfield (disambiguation). AnfieldView from the Sir Kenny Dalglish StandFull nameAnfieldLocationAnfield, Liverpool, EnglandPublic transit KirkdaleOwnerLiverpool F.C.OperatorLiverpool F.C.Executive suites64Capacity60,725[2]Record attendance61,905 (Liverpool–Wolverhampton Wanderers, 2 February 1952)Fiel...

Filmmaking in Qatar Part of a series on theCulture of Qatar History PeopleQataris Languages Traditions Clothing Mythology and folklore May and Gilan Cuisine Festivals Public holidays Religion Art Architecture of Qatar Collecting practices of the Al-Thani Family Public art in Qatar Literature Qatari folklore Music and performing arts Media Radio Television Cinema Sport Monuments World Heritage Sites Symbols Flag Coat of arms National anthem vte Cinema in Qatar is a relatively young industry th...

乔冠华 中华人民共和国外交部部长 中国人民对外友好协会顾问 任期1974年11月—1976年12月总理周恩来 → 华国锋前任姬鹏飞继任黄华 个人资料性别男出生(1913-03-28)1913年3月28日 中華民國江蘇省盐城县逝世1983年9月22日(1983歲—09—22)(70歲) 中华人民共和国北京市籍贯江蘇鹽城国籍 中华人民共和国政党 中国共产党配偶明仁(1940年病逝) 龚澎(1970年病逝) 章含�...

سورة يوسف سورة يوسف الترتيب في المصحف 12 إحصائيات السُّورة عدد الآيات 111 عدد الكلمات 1776 عدد الحروف 7166[1] الجزء 12-13 تَرتيب السُّورة في المُصحَف سورة هود سورة الرعد نُزول السُّورة النزول مكية ترتيب نزولها 52 سورة هود سورة الحجر نص السورة برواية حفص لقراءة عاصم برواية ورش لق�...

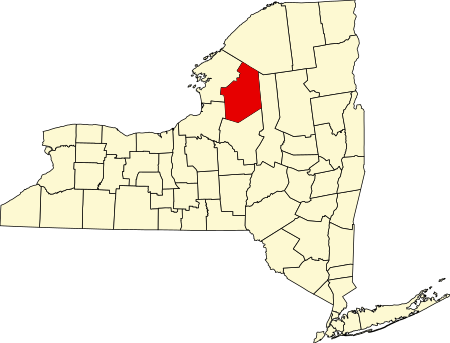

لمعانٍ أخرى، طالع مقاطعة لويس (توضيح). مقاطعة لويس الإحداثيات 43°47′N 75°27′W / 43.79°N 75.45°W / 43.79; -75.45 [1] تاريخ التأسيس 1805 سبب التسمية مورغان لويس تقسيم إداري البلد الولايات المتحدة[2] التقسيم الأعلى نيويورك العاصمة قرية لوفيل...

Southeast Asian archipelago Indonesian ArchipelagoNative name: Kepulauan IndonesiaEtymology Indonesia from Greek: Ινδο (Indo, lit. 'Indies') + νησιά (nisiá, lit. 'islands') Nusantara from Javanese: ꦤꦸꦱ (Nusa, lit. 'islands') + ꦲꦤ꧀ꦠꦫ (antara, lit. 'outer') GeographyLocationSoutheast AsiaAdjacent to Indian Ocean Oceania Pacific Ocean Total islands± 17,000–18,000 islands[1][2]Major islands Java Kalimantan Maluku Islands Papua Sumatra Sulawesi Area8,30...

Irish footballer and manager For other people named Joe Dunne, see Joe Dunne (disambiguation). Joe DunnePersonal informationFull name Joseph John Dunne[1]Date of birth (1973-05-25) 25 May 1973 (age 51)[1]Place of birth Dublin, Ireland[1]Height 5 ft 8 in (1.73 m)[2]Position(s) DefenderYouth career1989–1990 GillinghamSenior career*Years Team Apps (Gls)1990–1996 Gillingham 115 (1)1996–1999 Colchester United 98 (3)1999 Dover Athletic 11 (2...

Ancient Mayan city in Chiapas, Mexico Q'YaxchilanStructure 33 at YaxchilanLocation of the siteShow map of MesoamericaYaxchilan (Mexico)Show map of MexicoLocationChiapas, MexicoCoordinates16°54′N 90°58′W / 16.900°N 90.967°W / 16.900; -90.967TypeSettlementHistoryCulturesMaya civilizationSite notesConditionIn ruins Yaxchilan (pronounced [ʝaʃtʃiˈlan]) is an ancient Maya city located on the bank of the Usumacinta River in the state of Chiapas, Mexico. In...

American actor (1902–1952) For the boxer, see Dick Curtis (boxer). For the Irish Gaelic footballer, see Dick Curtis (Gaelic footballer). Dick CurtisCurtis in Lady in the Death House (1944)BornRichard Dye(1902-05-11)May 11, 1902Newport, Kentucky, U.S.DiedJanuary 3, 1952(1952-01-03) (aged 49)Los Angeles, California, U.S.Resting placeHoly Cross Cemetery, Culver City, CaliforniaYears active1919–1952Spouse Ruth Sullivan (m. 1925)ChildrenJohn...