Messerschmitt-Bölkow-Blohm

| |||||||||||||||||||||||

Read other articles:

Untuk kegunaan lain, lihat ATUC (disambiguasi). Koordinat: 41°06′41″N 48°36′50″E / 41.11139°N 48.61389°E / 41.11139; 48.61389 AtucAtucKoordinat: 41°06′41″N 48°36′50″E / 41.11139°N 48.61389°E / 41.11139; 48.61389Negara AzerbaijanRayonQubaMunisipalitasAfurcaPopulasi (2009) • Total19Zona waktuUTC+4 (AZT) • Musim panas (DST)UTC+5 (AZT) Atuc (juga Atuch) adalah sebuah desa di Rayon Quba, Azerb...

Christy CanyonCanyon, Februari 2006Lahir17 Juni 1966 (umur 57)[1]Pasadena, California, Amerika SerikatNama lainChristie Canyon, Cristy Canyon, Missy, Tara White, Sara Wine, Tara Wine, Linda Daniel, DeeDeeTinggi5 ft 7 in (1,70 m)Berat130 pon (59 kg; 9,3 st)Situs webwww.christycanyon.com Christy Canyon (lahir 17 Juni 1966)[1] adalah mantan aktris porno dan penyiar radio asal Amerika Serikat.[3] Dirinya telah dilantik menjadi anggo...

BMW Z4 (E85 & E86)InformasiProdusenBMWMasa produksiSeptember 2002 – Agustus 2008 (Roadster)PerakitanGreer, Spartanburg County, South Carolina, United States (BMW US Mfg. Co.)PerancangAnders Warming (1999)Bodi & rangkaKelasMobil mewah-sport-RoadsterBentuk kerangka2-door Roadster2-door coupéTata letakFMR layoutPenyalur dayaMesin2.0 L N46B20 I42.2 L M54B22 I62.5 L M54B25 I63.0 L M54B30 I63.0 L N52B30 I63.2 L S54B32 I6Transmisi5/6-speed manual5/6-spee...

Artikel ini sebatang kara, artinya tidak ada artikel lain yang memiliki pranala balik ke halaman ini.Bantulah menambah pranala ke artikel ini dari artikel yang berhubungan atau coba peralatan pencari pranala.Tag ini diberikan pada November 2022. Cha Dong-hoonInformasi pribadiTanggal lahir 7 November 1989 (umur 34)Tempat lahir Korea SelatanPosisi bermain PenyerangKarier senior*Tahun Tim Tampil (Gol)2009 FC Gifu 2009 FC Kariya * Penampilan dan gol di klub senior hanya dihitung dari liga do...

Surat paten yang dikeluarkan oleh Ratu Victoria pada tahun 1900, untuk membuat jabatan baru Gubernur Jenderal Australia sebagai bagian dari proses Federasi. Surat paten adalah jenis instrumen hukum dalam bentuk perintah tertulis yang dikeluarkan oleh Kerajaan, presiden, atau kepala negara lainnya, yang umumnya berisi jaminan untuk kantor, hak, monopoli, jabatan, atau status kepada seseorang atau korporasi. Pranala luar Wikimedia Commons memiliki media mengenai Letters patent. Research Guide o...

Japanese footballer (born 1996) Daichi Kamada鎌田 大地 Kamada with Eintracht Frankfurt in 2022Personal informationFull name Daichi Kamada[1]Date of birth (1996-08-05) 5 August 1996 (age 27)[2][3]Place of birth Iyo, Japan[2]Height 1.80 m (5 ft 11 in)[3][4]Position(s) Attacking midfielderforwardTeam informationCurrent team LazioNumber 6Youth career0000–2008 Kids FC2009–2012 Gamba Osaka2012–2014 Higashiyama High School...

Pour les articles homonymes, voir Sole (homonymie). Sole Nom vulgaire ou nom vernaculaire ambigu :l'appellation « Sole » s'applique en français à plusieurs taxons distincts. Sole commune Taxons concernés De nombreuses espèces de la famille des Soleidae dont la Sole commune Plusieurs espèces du genre Cynoglossus de la famille des Cynoglossidae Plusieurs espèces du genre Trinectes de la famille des Achiridae Plusieurs espèces du genre Achirus de la famille des Achiridae...

Evening meal Part of a series onMeals Meals Suhur Breakfast Second breakfast Elevenses Brunch Lunch Tea Merienda Tiffin Dinner Supper Iftar Siu yeh Snack Combination meal Kids' meal Value meal Components and courses Full-course dinner Tasting menu Amuse-bouche Hors d'oeuvre Soup Entrée Roast Main course Salad Side dish Entremets Dessert Savoury Meal preparation Related concepts À la carte Banquet Buffet Cuisine list Drink Eating Food Grazing History of breakfast Kamayan Table d'hôte Table ...

1949 novel by Cordwainer Smith Atomsk First ed. coverAuthorPaul LinebargerCountryUnited StatesGenreSpy novelPublished1949Media typePrint Atomsk, first published in 1949, is a Cold War spy novel by Carmichael Smith, one of several pseudonyms used by American writer Paul Linebarger, who wrote fiction most prolifically as Cordwainer Smith. Plot Drawing on Linebarger's own expertise in the field of psychological warfare, the book is a study of the personality of a U.S. operative (Major Micha...

Cet article est une ébauche concernant une chanson, le Concours Eurovision de la chanson et la Belgique. Vous pouvez partager vos connaissances en l’améliorant (comment ?) selon les recommandations des projets correspondants. Ik heb zorgen Chanson de Louis Neefs auConcours Eurovision de la chanson 1967 Sortie 1967 Langue Néerlandais Auteur Phil Van Cauwenbergh Compositeur Paul Quintens Chansons représentant la Belgique au Concours Eurovision de la chanson Un peu de poivre, un...

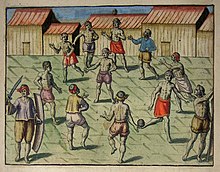

Sepak ragaParaga atau Maraga, variasi sepak raga yang berasal dari suku Bugis dan MakassarPertama dimainkanKepulauan Melayu[1][2][3]KarakteristikKontak fisikTidakAnggota timVariasiKategoriIndoor dan OutdoorPeralatanBola rattan, plastik karet sintetisKeberadaanOlimpiadeTidak Sepak raga (bahasa Minangkabau: sipak rago) adalah olahraga tradisional Indonesia dan Malaysia, yang dikembangkan di Kepulauan Melayu. Permainan ini berkaitan dengan sepak takraw modern. Permain...

2019 single by Charli XCX and Christine and the Queens GoneSingle by Charli XCX and Christine and the Queensfrom the album Charli Released17 July 2019 (2019-07-17)StudioLotus Library (Stockholm)Lotus Lounge (Los Angeles)Vincent Ave (Los Angeles)Genre Progressive pop[1] electropop[2][3] synth-pop[4] funk-pop[5] industrial[6] Length4:05LabelAsylumAtlantic UKSongwriter(s)Charlotte AitchisonJonnali ParmeniusHéloïse LetissierLinus Wi...

Hospital in New York, United StatesCalvary HospitalGeographyLocation1740 Eastchester RoadMorris Park 10461, The Bronx, New York, United StatesOrganizationCare systemPrivateFundingNon-profit hospitalTypeTeachingServicesBeds225[1]SpecialityHospice and palliative care, affiliated with the Roman Catholic Archdiocese of New York[1]Public transit access New York City Bus: Bx21, Bx24, Bx31HistoryOpened1899LinksWebsitewww.calvaryhospital.orgListsHospitals in New York StateOther linksH...

Major river in West Africa Gambia RiverGambia River in the Niokolo-Koba National ParkMap of the Gambia River drainage basinLocationCountriesGuineaSenegalThe GambiaPhysical characteristicsSourceFouta Djallon • location Labé, Guinea • coordinates11°24′43″N 12°13′34″W / 11.412°N 12.226°W / 11.412; -12.226 • elevation795 m (2,608 ft) MouthAtlantic Ocean • locationBanjul, The Gambia&...

尼维涅和叙朗Nivigne et Suran 法國市镇尼维涅和叙朗的位置 尼维涅和叙朗显示法国的地图尼维涅和叙朗显示安省的地图坐标:46°15′51″N 5°25′39″E / 46.2641°N 5.4275°E / 46.2641; 5.4275国家 法國大区 奥弗涅-罗讷-阿尔卑斯大区省 安省区布雷斯地区布尔格区政府 • 市长 Bernard Prin(維基數據所列:Q65597191)面积1 • 市镇30.98 平方公...

Ukrainian ice dancer Julia GolovinaGolovina and Voiko in 2004Born (1982-05-30) 30 May 1982 (age 42)Kharkiv, Ukrainian SSRHeight1.65 m (5 ft 5 in)Figure skating careerCountryUkraine RussiaSkating clubDallas Figure Skating ClubBegan skating1986Retired2006 Medal record Figure skating: Ice dancing Representing Ukraine Winter Universiade 2005 Innsbruck Ice dancing Julia Golovina (born 30 May 1982) is a Ukrainian former competitive ice dancer. With former partner Oleg Voik...

EFL League TwoAltri nomiFourth Division (1959-1992)Third Division (1993-2004) Sport Calcio TipoSquadre di club FederazioneFA Paese Inghilterra Galles OrganizzatoreEnglish Football League Cadenzaannuale Aperturaagosto Chiusuramaggio Partecipanti24 squadre Formulagirone A/R+play-off Promozione inEFL League One Retrocessione inNational League Sito InternetFootball League Two StoriaFondazione1958 [1] Numero edizioni66 [2] Detentore Stockport County Record vittorie&#...

1961 studio album by Ernestine AndersonMy Kinda SwingStudio album by Ernestine AndersonReleasedNovember 1, 1961RecordedLate 1960, New York CityGenreVocal jazzLength37:24LabelMercuryErnestine Anderson chronology The Toast of the Nation's Critics(1960) My Kinda Swing(1961) Hello Like Before(1977) Professional ratingsReview scoresSourceRatingAllmusic[1]The Penguin Guide to Jazz Recordings[2] My Kinda Swing is a 1961 studio album by Ernestine Anderson, arranged by Ernie Wi...

For the San Diego neighborhood, see Otay Mesa, San Diego. Borough of Tijuana in Baja California, MexicoOtay CentenarioBorough (Delegación) of TijuanaDelegación Otay CentenarioOtay CentenarioLocation in TijuanaCoordinates: 32°32′09″N 116°56′35″W / 32.535856°N 116.943111°W / 32.535856; -116.943111CountryMexicoStateBaja CaliforniaMunicipality (municipio)TijuanaArea code664 Otay Centenario is a borough of the municipality of Tijuana in Baja California, Mexico...

この記事には複数の問題があります。改善やノートページでの議論にご協力ください。 脚注による出典や参考文献の参照が不十分です。脚注を追加してください。(2021年6月) 日本中心に書かれており、世界的観点からの説明がされていないおそれがあります。(2023年6月) アメリカ合衆国最高裁判所 Supreme Court of the United States 設置 1789年3月4日国 アメリカ合衆国�...