Hardwood

|

Read other articles:

Artikel ini adalah tentang Yaris hatchback, untuk Yaris sedan lihat Toyota Belta/Toyota Vios Toyota YarisInformasiProdusenToyotaJuga disebutToyota VitzMasa produksi1999–sekarangKesamaanHonda JazzHyundai GetzKia RioSuzuki SwiftBodi & rangkaKelasSubkompakBentuk kerangkaHatchback 3 atau 5 pintuKronologiPendahuluToyota StarletToyota Tercel Toyota Yaris atau Toyota Vitz adalah mobil hatchback kecil yang diproduksi oleh Toyota. Yaris diluncurkan pertama kali pada tahun 1999 di Eropa...

Golden Disc AwardsDeskripsiPencapaian luar biasa di industri musikNegaraSelatanDipersembahkan olehAsosiasi Industri Musik KoreaDiberikan perdana1986Situs webGolden Disk AwardsSiaran televisi/radioSaluranJTBC (2013) Golden Disc Awards (Hangul: 골든 디스크 어워드) adalah sebuah acara penghargaan yang pertama kali dilaksanakan pada tahun 1986 dan digelar setiap tahun oleh Asosiasi Industri Musik Korea Selatan untuk pencapaian luar biasa di industri musik Korea Selatan.[1]...

Sakdiyah Ma'rufLahirSakdiyah Ma'ruf11 Februari 1982 (umur 42)Pekalongan, IndonesiaNama lainDiyahPekerjaanDosen, penerjemah, Pelawak tunggalTahun aktif2011—sekarang Sakdiyah Ma'ruf (lahir 11 Februari 1982) adalah seorang pelawak tunggal dari Indonesia. Perempuan yang akrab disapa Diyah ini merupakan pelawak tunggal wanita pertama yang berhijab di Indonesia. Diyah dikenal melalui humor-humornya yang membahas seputar Islam untuk mengatasi ekstremisme Islam di Indonesia. Kehidup...

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages) The neutrality of this article is disputed. Relevant discussion may be found on the talk page. Please do not remove this message until conditions to do so are met. (September 2022) (Learn how and when to remove this template message) This article needs additional citations for verification. Please help improve this article by adding citation...

هذه المقالة تحتاج للمزيد من الوصلات للمقالات الأخرى للمساعدة في ترابط مقالات الموسوعة. فضلًا ساعد في تحسين هذه المقالة بإضافة وصلات إلى المقالات المتعلقة بها الموجودة في النص الحالي. (فبراير 2023) ليرة مالطيةمعلومات عامةالبلد مالطا تاريخ الإصدار 7 يونيو 1972 عوض جنيه مالطي عو�...

The Right HonourableEarl Lloyd-George dari DwyforOM Perdana Menteri Britania RayaMasa jabatan7 Desember 1916 – 22 Oktober 1922Penguasa monarkiGeorge V PendahuluHerbert Henry AsquithPenggantiAndrew Bonar LawChancellor of the ExchequerMasa jabatan12 April 1908 – 25 Mei 1915Perdana MenteriHerbert Henry Asquith PendahuluHerbert Henry AsquithPenggantiReginald McKennaSekretaris Negara untuk PerangMasa jabatan6 Juni 1916 – 5 Desember 1916Perdana MenteriHerbert Henry ...

2023 Louisiana House of Representatives election ← 2019 October 14, 2023November 18, 2023 (runoff) 2027 → All 105 seats in the Louisiana House of Representatives53 seats needed for a majority Majority party Minority party Third party Leader Clay Schexnayder(term-limited) Sam Jenkins(retired) Joseph A. Marino III(retired) Party Republican Democratic Independent Leader since January 13, 2020 January 13, 2020 July 1, 2016 Leader's seat 81st district...

Koordinat: 58°12′N 6°36′W / 58.2°N 6.6°W / 58.2; -6.6 Lewis bahasa Gaelik Skotlandia: Leòdhasⓘ Pulau Lewis Bahasa Gaelik Skotlandia Inggris Ref. grid OS NB426340 - Edinburgh 276 Miles Wilayah dewan Na h-Eileanan Siar Wilayah keletnanan Western Isles Negara konstituen Skotlandia Negara berdaulat Britania Raya Kota pos STORNOWAY ISLE OF LEWIS Distrik kode pos HS1, HS2 Kode tel...

1996 World JuniorChampionships in AthleticsTrack events100 mmenwomen200 mmenwomen400 mmenwomen800 mmenwomen1500 mmenwomen3000 mwomen5000 mmenwomen10,000 mmen100 m hurdleswomen110 m hurdlesmen400 m hurdlesmenwomen3000 msteeplechasemen4 × 100 m relaymenwomen4 × 400 m relaymenwomen5000 m walkwomen10,000 m walkmenField eventsHigh jumpmenwomenPole vaultmenLong jumpmenwomenTriple jumpmenShot putmenwomenDiscus throwmenwomenHammer throwmenJavelin throwmenwomenCombined eventsHeptathlonwomenDecathlo...

Синелобый амазон Научная классификация Домен:ЭукариотыЦарство:ЖивотныеПодцарство:ЭуметазоиБез ранга:Двусторонне-симметричныеБез ранга:ВторичноротыеТип:ХордовыеПодтип:ПозвоночныеИнфратип:ЧелюстноротыеНадкласс:ЧетвероногиеКлада:АмниотыКлада:ЗавропсидыКласс:Пт�...

Questa voce o sezione sull'argomento centri abitati della Germania non cita le fonti necessarie o quelle presenti sono insufficienti. Puoi migliorare questa voce aggiungendo citazioni da fonti attendibili secondo le linee guida sull'uso delle fonti. Oberstdorfcomune Oberstdorf – Veduta LocalizzazioneStato Germania Land Baviera Distretto Svevia CircondarioAlta Algovia TerritorioCoordinate47°23′N 10°16′E / 47.383333°N 10.266667°E47.383333; 10.266667�...

Questa voce sull'argomento cestisti statunitensi è solo un abbozzo. Contribuisci a migliorarla secondo le convenzioni di Wikipedia. Segui i suggerimenti del progetto di riferimento. Thomas Bryant Thomas Bryant con la maglia dei Washington Wizards Nazionalità Stati Uniti Altezza 208 cm Peso 112 kg Pallacanestro Ruolo Centro Squadra Miami Heat CarrieraGiovanili Bishop Kearney High SchoolHuntington Prep High School2015-2017 Indiana HoosiersSquadre di club 2017-2018 ...

Veikkausliiga 2018 Competizione Veikkausliiga Sport Calcio Edizione 109ª Organizzatore SPL/FBF Date dal 7 aprile 2018al 27 ottobre 2018 Luogo Finlandia Partecipanti 12 Formula Girone all'italiana Sito web Veikkausliiga Risultati Vincitore HJK(29º titolo) Secondo RoPS Retrocessioni TPSPS Kemi Kings Statistiche Miglior marcatore Klauss (21) Incontri disputati 198 Gol segnati 490 (2,47 per incontro) Cronologia della competizione 2017 2019 Manuale HJK Inter TurkuTPS Tur...

Radio station in Erie, Pennsylvania WQHZErie, PennsylvaniaBroadcast areaErie, PennsylvaniaFrequency102.3 MHzBrandingZ102.3ProgrammingFormatClassic rockAffiliationsWestwood OneOwnershipOwnerCumulus Media(Radio License Holding CBC, LLC)Sister stationsWRIE, WXTA, WXKCHistoryFirst air date1971 (as WMDI-FM)Former call signsWMDI-FM (1971–1980)WSEG (1980–1986)WJET-FM (1986–2001)WLKK (6/2001-10/2001)Technical informationFacility ID65748ClassAERP1,700 wattsHAAT187 meters (614 ft)LinksWebcas...

القاهرة معلومات عامة النوع منوعات المالك اتحاد الإذاعة والتلفزيون المصري المدير محمد العمري تاريخ التأسيس أكتوبر 1985 (منذ 38 سنة) البلد مصر اللغة العربية اسم قديم الثالثة المصرية الإقليمية(القنوات الأخرى) القنال الإسكندرية الدلتا الصعيد طيبة المقر الرسمي ماسبيرو الموق...

For the Stadium and home of Scottish Rugby Union, see Murrayfield Stadium. For the area in the Wimbledon grounds named after Andy Murray, see Henman Hill. Murrayfield House, Edinburgh Murrayfield Stadium Murrayfield Ice Rink Murrayfield is an area to the west of Edinburgh city centre in Scotland.[1] It is to the east of Corstorphine and north of Balgreen, Saughtonhall and Roseburn. The A8 road runs east–west through the south of the area. Murrayfield is often considered to include ...

Elezioni regionali in Abruzzo del 2019Stato Italia Regione Abruzzo Data10 febbraio Affluenza53,11% ( 8,44%) Candidati Marco Marsilio Giovanni Legnini Sara Marcozzi Partiti Fratelli d'Italia Indipendente Movimento 5 Stelle Coalizioni Centro-destra Centro-sinistra nessuna Voti 299.94948,03% 195.39431,28% 126.16520,20% Seggi 18 / 30 6 / 30 7 / 30 Distribuzione del voto per comune Presidente uscenteGiovanni Lolli (PD) - ad interim 2014 2024 Le elezioni regionali in Abruzzo del 2019 si ...

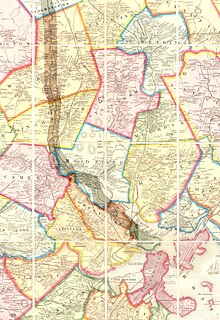

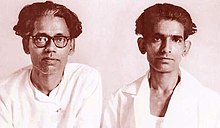

Indian film directing duo Krishnan–PanjuKrishnan (left) and Panju (right)BornR. Krishnan:(1909-07-18)18 July 1909S. Panju:(1915-01-24)24 January 1915R. Krishnan:Chennai, Tamil NaduS. Panju:Umayalpuram, Kumbakonam, Tamil NaduDiedR. Krishnan:17 July 1997(1997-07-17) (aged 87)S. Panju:6 April 1984(1984-04-06) (aged 69)Chennai, Tamil Nadu, IndiaOccupationFilm directorsYears activeR. Krishnan:1944–1997S. Panju:1944–1984 R. Krishnan (1909–1997) and S. Panju (1915–1984), col...

Artikel ini sebatang kara, artinya tidak ada artikel lain yang memiliki pranala balik ke halaman ini.Bantulah menambah pranala ke artikel ini dari artikel yang berhubungan atau coba peralatan pencari pranala.Tag ini diberikan pada Desember 2023. Robert Rob Maingay (lahir 24 Februari 1939) adalah pematung, arsitek, dan pembuat mebel Belanda. Kehidupan dan karya Maingay belajar di Akademi Seni Rupa dan Ilmu Teknik di Rotterdam. Sang pematung ini tinggal dan bekerja di Vreewijk, Rotterdam, yang ...

يفتقر محتوى هذه المقالة إلى الاستشهاد بمصادر. فضلاً، ساهم في تطوير هذه المقالة من خلال إضافة مصادر موثوق بها. أي معلومات غير موثقة يمكن التشكيك بها وإزالتها. (ديسمبر 2018) مسجد أبو قورة معلومات عامة الدولة الأردن تعديل مصدري - تعديل صورة جانبية للمسجد مسجد الحاج صالح أب...