Functional safety

|

Read other articles:

Richard IIPotret di Biara Westminster, Pertengahan Tahun 1390Raja InggrisBerkuasa22 Juni 1377 – 29 September 1399 (22 tahun, 99 hari)Penobatan16 Juli 1377PendahuluEdward IIIPenerusHenry IVWaliJohn dari Gaunt, Adipati Pertama Lancaster (de facto)Informasi pribadiPemakamanBiara Westminster, LondonWangsaWangsa PlantagenetAyahEdward, Pangeran HitamIbuJoan dari KentPasanganAnne dari Bohemiamenikah tahun 1382; menjanda Desember 1394Isabella dari Valoismenikah tahun 1396; menjanda tahun ...

Bagian dari seri tentangBuddhisme SejarahPenyebaran Sejarah Garis waktu Sidang Buddhis Jalur Sutra Benua Asia Tenggara Asia Timur Asia Tengah Timur Tengah Dunia Barat Australia Oseania Amerika Eropa Afrika Populasi signifikan Tiongkok Thailand Jepang Myanmar Sri Lanka Vietnam Kamboja Korea Taiwan India Malaysia Laos Indonesia Amerika Serikat Singapura AliranTradisi Buddhisme prasektarian Aliran Buddhis awal Mahāsāṃghika Sthaviravāda Aliran kontemporer Theravāda Mahāyāna Vajrayāna Kon...

Mountain in the American state of California Mount StewartWest aspectHighest pointElevation12,205+ ft (3721+ m) NAVD 88[1]Prominence440 ft (134 m)[1]ListingSierra Peaks Section[2]Coordinates36°34′11″N 118°33′16″W / 36.5696616°N 118.5545389°W / 36.5696616; -118.5545389[3]GeographyMount StewartLocation of Mount Stewart in California LocationTulare County, California, U.S.Parent rangeSierra NevadaTopo ma...

1910 painting made by Henri Matisse For the mural by Matisse, see The Dance II. This article uses bare URLs, which are uninformative and vulnerable to link rot. Please consider converting them to full citations to ensure the article remains verifiable and maintains a consistent citation style. Several templates and tools are available to assist in formatting, such as reFill (documentation) and Citation bot (documentation). (August 2022) (Learn how and when to remove this message) DanceArtistH...

Public park located in Fresno, California, US Woodward ParkLakeside of Woodward ParkNearest cityFresno, California, USArea300 acres (120 ha)Opened1968Operated byCity of Fresno Parks Department Woodward Park is a public park located in Fresno, California, abutting the San Joaquin River, opened in 1968. It is named after the late Ralph Woodward who bequeathed a portion of his estate to provide a regional park and bird sanctuary in Fresno. The park has a multi-use amphitheatre, an...

German publishing house BlanvaletParent companyVerlagsgruppe Penguin Random House (Bertelsmann)Founded1935FounderNicola BartelsCountry of originGermanyHeadquarters locationMunichPublication typesfiction, non-fictionOfficial websitewww.blanvalet.de Blanvalet is a German publishing house, based in Munich, which was founded in 1935 in Berlin and is now part of the Bertelsmann's Random House publishing group.[1] Blanvalet publishes entertainment literature and non-fiction, first in hardco...

Universitas Sintuwu MarosoNama lainUNSIMARMotoCerdas, Kreatif, dan ProfesionalJenisPerguruan tinggi swastaDidirikan1986PendiriJ. SantoRektorSuwardhi PantihStaf akademik103 (Januari 2014)Staf administrasi42 (karyawan)Jumlah mahasiswa5238 (2015-1)Sarjana2251 (2015-1)AlamatJl. P. Timor, Poso, Sulawesi Tengah, 94619, IndonesiaSitus webunsimar.ac.id Universitas Sintuwu Maroso, atau umumnya dikenal dengan singkatan UNSIMAR, adalah sebuah perguruan tinggi swasta yang berada di Poso, Sulawesi Tengah,...

Study of postulating possible, probable, and preferable futures Futurology redirects here. For other uses, see Futurology (disambiguation). For the study of the futures financial instrument, see futures contract and futures exchange. Not to be confused with Futurism. Moore's law is an example of futurology; it is a statistical collection of past and present trends with the goal of accurately extrapolating future trends. Futures studies Concepts Accelerating change Cashless society Existential...

Ria IrawanLahirChandra Ariati Dewi Irawan(1969-07-24)24 Juli 1969Jakarta, IndonesiaMeninggal6 Januari 2020(2020-01-06) (umur 50)Jakarta, IndonesiaNama lainRia IrawanPekerjaan Aktris Penyanyi Tahun aktif1973–2020Suami/istri Yuma Wiranatakusumah (m. 1997; c. 1999) Mayky Wongkar (m. 2016; meninggal 2020) Orang tuaBambang Irawan (ayah) Ade Irawan (ibu)KerabatDewi Irawan (kakak...

聖胡安群島地圖 聖胡安群島(英語:San Juan Islands)是美國西北部太平洋沿岸的一個群島,位於薩利希海中央。在行政區劃上,聖胡安群島屬於美國華盛頓州聖胡安縣。聖胡安群島與本土之間藉由華盛頓州渡輪(英语:Washington State Ferries)往來[1]。現在聖胡安群島是一個著名的旅遊目的地,以賞鯨活動而著稱。 島嶼 聖胡安島 奧爾克斯島 羅培茲島 肖島 參閱 豬戰 參考�...

DART light rail station in Dallas, Texas MLK Jr.DART light rail stationGeneral informationLocation1412 South Trunk AvenueDallas, TX 75210Coordinates32°46′26″N 96°45′52″W / 32.773754°N 96.764575°W / 32.773754; -96.764575Platforms2 side platformsTracks2ConnectionsDART Routes 13, 23, 104, and 216 South Dallas GoLink Zone (M-Sun)ConstructionParking200 spaces[1]AccessibleYesHistoryOpenedFebruary 21, 2005[2] (bus)September 14, 2009[3] (rai...

فيجوال بيسك للتطبيقاتالشعارمعلومات عامةالتصنيف تنفيذ لغات البرمجة — فيجوال بيسك — لغة برمجة التنميط البرمجة متعددة الأنماط مقتبس من فيجوال بيسك ظهرت في 1993 التطويرالمطور مايكروسوفت الإصدار الأول 1993 الإصدار الأخير 7.1 (2012) التأثيرمشتقة من فيجوال بيسك متأثرة بـ فيجوال بيسك...

This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed.Find sources: Ranpur, Gujarat – news · newspapers · books · scholar · JSTOR (May 2012) (Learn how and when to remove this message) Town in Gujarat, IndiaRanpurtownRanpurLocation in Gujarat, IndiaShow map of GujaratRanpurRanpur (India)Show map of IndiaCoordinates: 22°22′3...

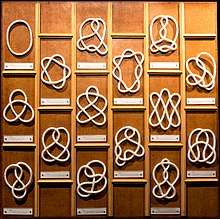

Study of mathematical knots Examples of different knots including the trivial knot (top left) and the trefoil knot (below it) A knot diagram of the trefoil knot, the simplest non-trivial knot In topology, knot theory is the study of mathematical knots. While inspired by knots which appear in daily life, such as those in shoelaces and rope, a mathematical knot differs in that the ends are joined so it cannot be undone, the simplest knot being a ring (or unknot). In mathematical language, a kno...

For the snake genus, see Platyplectrurus. King of the Visigoths WalhaKing of the VisigothsImaginary portrait of Wallia by Alejo Vera. 1855. (Museo del Prado, Madrid)Reign415–418PredecessorSigericSuccessorTheodoric IDied418DynastyBalti dynastyFatherPossibly Athanaric IMotherRocestes Wallia, Walha or Vallia (Spanish: Walia, Portuguese Vália), (c. 385 – 418) was king of the Visigoths from 415 to 418, earning a reputation as a great warrior and prudent ruler. He was elected to the throne aft...

Jenoisegénoise (بالفرنسية) معلومات عامةالمنشأ فرنسا النوع كعكة إسفنجية المكونات الرئيسية طحين تعديل - تعديل مصدري - تعديل ويكي بيانات الجِنويَّة أو الكعكة الجِنَوِيّة أو كعكة الجنواز[1] أو جاتوه الجينواز[2] أو عجين جينواز[3] (بالفرنسية: génoise) هي كعكة إسفنجية إيطالية ت�...

علم اجتماع العائلةصنف فرعي من علم الاجتماع — family science (en) الموضوع أسرة تعديل - تعديل مصدري - تعديل ويكي بيانات علم اجتماع العائلة هو علم يدرس مراحل تطور ونمو الأسرة ابتداءً من الأسرة النواة والتي يتم تكوينها من الزوجين والأبناء حتي وصولها إلى الأسرة الممتدة، التي تتكون من ال...

Voce principale: Eccellenza 2004-2005. Eccellenza Veneto 2004-2005 Competizione Eccellenza Veneto Sport Calcio Edizione 14ª Organizzatore FIGC - LNDComitato Regionale Veneto Luogo Italia Cronologia della competizione 2003-2004 2005-2006 Manuale Il campionato italiano di calcio di Eccellenza regionale 2004-2005 è stato il quattordicesimo organizzato in Italia. Rappresenta il sesto livello del calcio italiano. Questi sono i gironi organizzati dal comitato regionale della regione Veneto...

French actress (1919–2014) For other people with the same name, see Labourdette. Élina LabourdetteBorn(1919-05-21)21 May 1919Paris, FranceDied30 September 2014(2014-09-30) (aged 95)Le Mesnil-le-Roi,Yvelines, FranceOther namesÉlina Janine Alice Henri-LabourdetteOccupationActressYears active1938–1983Known forLes Dames du Bois de Boulogne (1945)Edward and Caroline (1951)Spouse Louis Pauwels (m. 1956; died 1997)Children...

Bagian dari seriIslam Rukun Iman Keesaan Allah Malaikat Kitab-kitab Allah Nabi dan Rasul Allah Hari Kiamat Qada dan Qadar Rukun Islam Syahadat Salat Zakat Puasa Haji Sumber hukum Islam al-Qur'an Sunnah (Hadis, Sirah) Tafsir Akidah Fikih Syariat Sejarah Garis waktu Muhammad Ahlulbait Sahabat Nabi Khulafaur Rasyidin Khalifah Imamah Ilmu pengetahuan Islam abad pertengahan Penyebaran Islam Penerus Muhammad Budaya dan masyarakat Akademik Akhlak Anak-anak Dakwah Demografi Ekonomi Feminisme Filsafat...