Boring (manufacturing)

|

Read other articles:

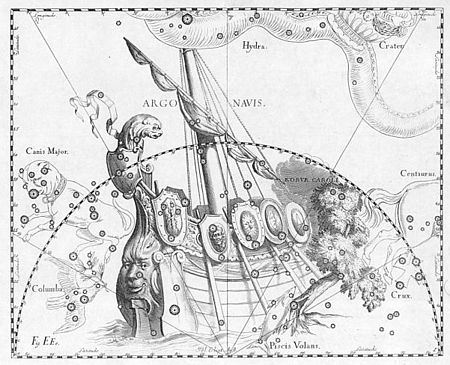

Rasi Argo Navis digambar oleh Johannes Hevelius pada 1690 Argo Navis (sering dipendekkan sebagai Argo saja) adalah sebuah rasi bintang yang luas, di belahan langit selatan. Di dalam mitologi Yunani kuno, rasi ini melambangkan Argo, kapal yang digunakan oleh Jason dan para Argonauts. Singkatannya adalah Arg dan nama genitifnya adalah Argūs. Rasi ini adalah satu-satunya rasi di dalam daftar 48 rasi Ptolemaeus yang tidak diadopsi ke dalam 88 daftar rasi bintang IAU, sebab telah dipecah menjadi ...

1991 television film directed by Rupert Wainwright DillingerGenreActionBiographyCrimeDramaHistoryWritten byPaul F. EdwardsDirected byRupert WainwrightStarringMark HarmonSherilyn FennWill PattonBruce AbbottTheme music composerDavid McHughCountry of originUnited StatesOriginal languageEnglishProductionExecutive producerDavid L. WolperProducersMark WolperBernard Sofronski (delegate producer)Art Levinson (associate producer)Production locationsEast Troy, WisconsinMequon, Wisconsin (Shoot out at L...

Участники австрийской фольклорной группы в народных костюмах Трахт (нем. Tracht) — традиционный национальный костюм в немецкоговорящих странах. Несмотря на то, что во всём мире чаще всего ассоциируется с австрийским и баварским костюмами, он распространён практически н...

American politician James Henry McLeanMember of the U.S. House of Representativesfrom Missouri's 2nd districtIn officeDecember 15, 1882 – March 3, 1883Preceded byThomas AllenSucceeded byArmstead M. Alexander Personal detailsBorn(1829-08-13)August 13, 1829Ayrshire, ScotlandDiedAugust 12, 1886(1886-08-12) (aged 56)Dansville, New York, U.S.Resting placeBellefontaine Cemetery, St. Louis, Missouri, U.S.Political partyRepublicanSignature James Henry McLean (August 13, 18...

Northern Irish comedian and actor (born 1963) Michael SmileySmiley in 2016Born (1963-01-29) 29 January 1963 (age 61)Belfast, Northern IrelandOccupation(s)Comedian, actorSpouseMiranda SawyerChildren4 Michael Smiley (born 29 January 1963)[1] is a Northern Irish comedian and actor. He is perhaps best known for his roles in the films Kill List (2011) and The Lobster (2015). He has also made appearances in British television series such as Luther, Utopia, Black Mirror and Doctor Who. ...

Voce principale: Associazione Sportiva Dilettantistica Città di Cerveteri. Associazione Sportiva CerveteriStagione 1993-1994Sport calcio Squadra Cerveteri Allenatore Vincenzo Ceripa poi Renato Scarpellino poi Stefano Di Chiara Presidente Leonardo Facchinetti Serie C213º posto nel girone C. Non ammesso alla Serie C2 1994-95 per problemi finanziari. Maggiori presenzeCampionato: Pierobon (32) Miglior marcatoreCampionato: Contestabile (6) 1992-1993 Si invita a seguire il modello di voce Q...

この項目には、一部のコンピュータや閲覧ソフトで表示できない文字が含まれています(詳細)。 数字の大字(だいじ)は、漢数字の一種。通常用いる単純な字形の漢数字(小字)の代わりに同じ音の別の漢字を用いるものである。 概要 壱万円日本銀行券(「壱」が大字) 弐千円日本銀行券(「弐」が大字) 漢数字には「一」「二」「三」と続く小字と、「壱」「�...

「俄亥俄」重定向至此。关于其他用法,请见「俄亥俄 (消歧义)」。 俄亥俄州 美國联邦州State of Ohio 州旗州徽綽號:七葉果之州地图中高亮部分为俄亥俄州坐标:38°27'N-41°58'N, 80°32'W-84°49'W国家 美國加入聯邦1803年3月1日,在1953年8月7日追溯頒定(第17个加入联邦)首府哥倫布(及最大城市)政府 • 州长(英语:List of Governors of {{{Name}}}]]) •&...

Harley-Davidson, Inc.JenisPublikKode emitenNYSE: HOGKomponen S&P 400IndustriKendaraan rekreasiDidirikan1903; 121 tahun lalu (1903)PendiriWilliam S. HarleyArthur DavidsonWalter Davidson William A. DavidsonKantorpusat Milwaukee, Wisconsin, Amerika SerikatTokohkunciJochen Zeitz (CEO dan chairman)[1]ProdukSepeda motorProduksi 241.498 unit (2017)[2]Pendapatan US$5,647 miliar (2017)[2]Laba operasi US$891 juta (2017)[2]Laba bersih US$522 juta (2017)[...

Kaspersky LabJenisSwastaIndustriPerangkat lunak komputer Perangkat lunak keamananDidirikanMoskow, Rusia (1997)PendiriEugene KasperskyKantorpusatMoskow, RusiaWilayah operasiSeluruh duniaTokohkunciEugene Kaspersky (CEO)ProdukKaspersky Anti-VirusKaspersky Internet SecurityKaspersky Mobile Security Kaspersky PURE Kaspersky Open Space Security Keamanan terintegrasiPendapatanUS$612 juta 14% (2011)[1]KaryawanLebih dari 2.400 (2011)[2]Situs webKaspersky.com Kaspersky Lab (pengucapan b...

Борис Миколайович Лятошинський Борис Миколайович ЛятошинськийІм'я при народженні Борис Миколайович ЛятошинськийНародився 22 листопада (4 грудня) 1894[4][5]Житомир, Російська імперія[1]Помер 15 квітня 1968(1968-04-15)[1][2][…] (73 роки)Київ, Українська РСР, СРСР[1]...

American politician This article is about the South Carolina politician. For other uses, see Alan Wilson (disambiguation). Alan Wilson51st Attorney General of South CarolinaIncumbentAssumed office January 12, 2011GovernorNikki HaleyHenry McMasterPreceded byHenry McMaster Personal detailsBornAlan McCrory (1973-07-16) July 16, 1973 (age 50)West Columbia, South Carolina, U.S.Political partyRepublicanParentJoe Wilson (adoptive father)EducationFrancis Marion University (BA)University of S...

Tangled Ever AfterPoster filmSutradaraNathan GrenoByron HowardDitulis olehDaniel GersonPerusahaanproduksiWalt Disney PicturesWalt Disney Animation StudiosDistributorWalt Disney StudiosHome EntertainmentTanggal rilis 13 Januari 2012 (2012-01-13) Durasi6.28 menitNegaraAmerika SerikatBahasaInggris Tangled Ever After adalah sebuah film pendek animasi komputer Amerika 2012 yang disutradarai oleh Nathan Greno dan Byron Howard.[1] Film ini adalah sekuel dari film Walt Disney Animation S...

Former Museum MOMI logo. The ceiling of MOMI's animation area revolved. Its design was based on a 19th-century Praxinoscope. The Museum of the Moving Image (MOMI) was a museum of the history of cinema technology and media sited below Waterloo Bridge in London. It was opened on 15 September 1988 by Prince Charles and at the time, was the world's largest museum devoted entirely to cinema and television.[1] The museum formed part of the cultural complex on the South Bank of the River Tha...

7th episode of the 5th season of Scrubs My Way HomeScrubs episodeEpisode no.Season 5Episode 7Directed byZach BraffWritten byNeil Goldman Garrett DonovanFeatured musicAfrica by TotoManiac by Michael Sembello (performed by The Worthless Peons)We're Off to See the Wizard by Harold Arlen (performed by The Worthless Peons)Over the Rainbow by Harold Arlen and Yip Harburg, arrangement by Israel Kamakawiwo'ole (performed by The Worthless Peons)Production code505Original air dateJanuary 24,&...

Chak Tok Ich'aak IAjaw Tikalke-14 dalam silsilahPrasasti 26 di Tikal mencantumkan nama Chak Tok Ich'aak, meskipun tak jelas apakah ini merujuk kepada Chak Tok Ich'aak I atau Chak Tok Ich'aak II.[1]Berkuasa360?-378PendahuluK'inich Muwaan JolPenerusYax Nuun Ahiin IKematian14 Januari 378AyahK'inich Muwaan JolIbuLady Bahlam WayAgamaAgama Maya Chak Tok Ich'aak I (wafat 14 Januari 378) adalah seorang ajaw kota Maya Tikal. Ia naik tahta pada 7 Agustus 360? dan memerintah sampai kematiannya p...

奉天协和洋行成立1920年2月 (1920-02)代表人物蕨冈胜太郎總部中华民国奉天市(沈阳市)→满洲国奉天市富士町業務範圍烟草制造及贩卖奉天协和洋行是一家曾位于奉天满铁附属地的洋行,主要经营业务为烟草制造及销售。协和洋行原址为辽宁省沈阳市和平区南京北街113号。目前,该建筑现已不存[1]。 简介 1918年12月,日本人蕨冈胜太郎由朝鲜烟草株式会社转至奉天�...

自動車 > オートバイ > オートバイ競技 市販オートバイを改造して用いる「スーパーバイク」 オートバイ競技(オートバイきょうぎ、英: Motorcycle sport)は、オートバイやそれに類する乗り物に乗ってスピードや運転技術などを競うスポーツ。 バイク競技や二輪競技と呼ぶこともあるが、「バイク」「二輪」という単語には、原動機のない二輪車(=自転車)�...

Serie CSport Calcio TipoClub Paese Svizzera OrganizzatoreASF/SFV Cadenzaannuale Aperturasettembre Chiusuramaggio Formulavari gironi eliminatori Promozione inSerie Promozione StoriaFondazione1902 Soppressione1930 Numero edizioni26 Modifica dati su Wikidata · Manuale La Serie C è stata il livello di base del campionato svizzero di calcio. Organizzata dall'ASF/SFV, vide competere un numero di squadre variabile, suddivise in raggruppamenti geografici prevalentemente regionali. La magg...

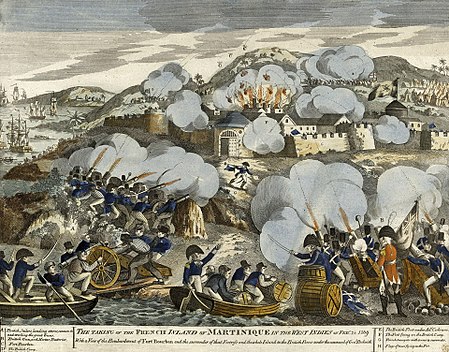

British victory during the Napoleonic Wars Invasion of MartiniquePart of the Napoleonic WarsThe Taking of the French Island of Martinique in the French West Indies on Feb 24th 1809, George ThompsonDate30 January – 24 February 1809LocationMartiniqueResult British victoryBelligerents United Kingdom FranceCommanders and leaders Alexander Cochrane George Beckwith Villaret de Joyeuse Strength 10,0006 ships of the line8 frigates9 brigs 4,900 3 brigsCasualties and losses 97 killed 365 wounde...